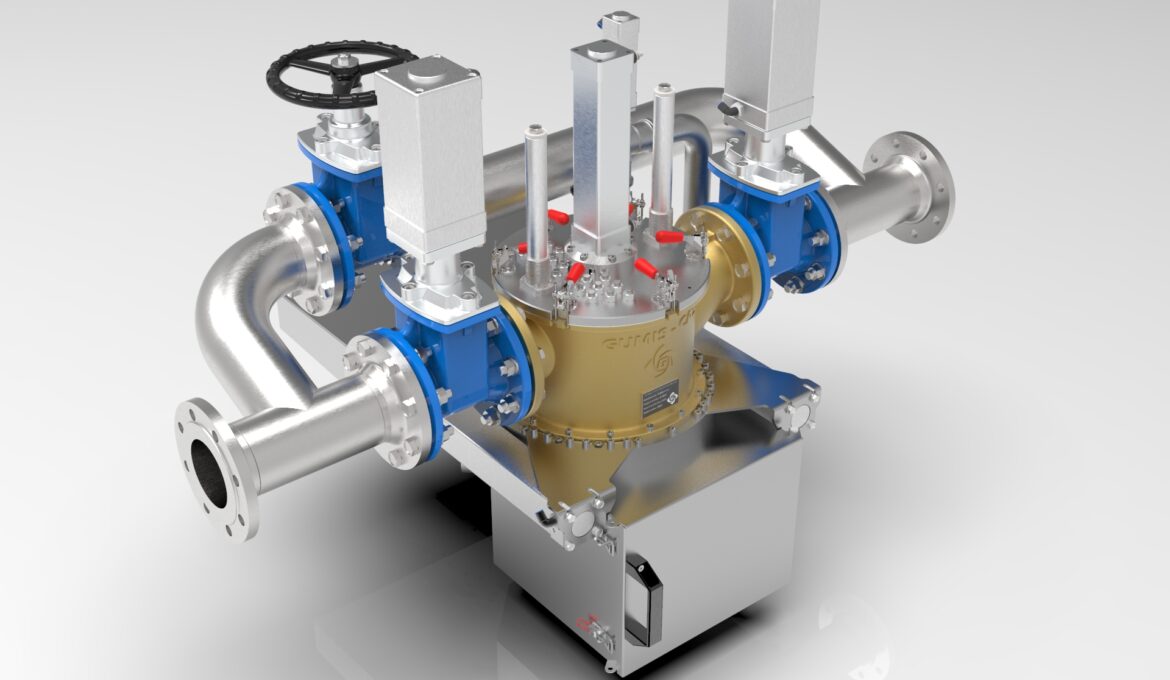

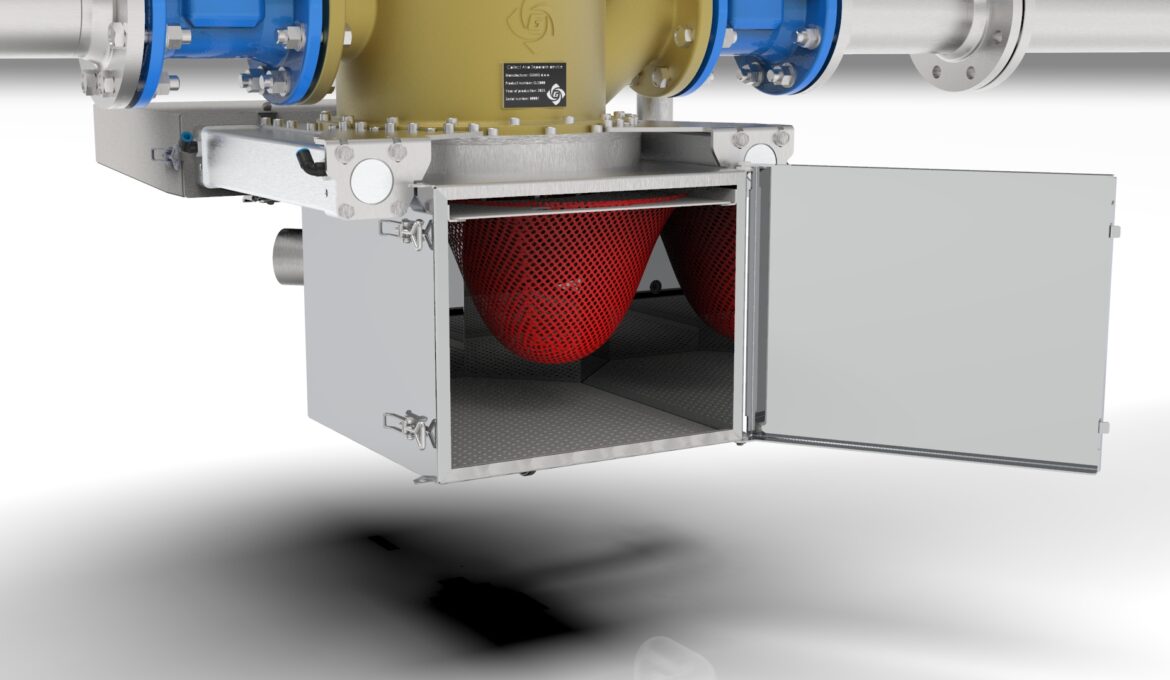

Collect And Separate (CAS) device

Introducing the Collect And Separate (CAS) device – a groundbreaking system engineered for the automatic separation, collection, and expulsion of hazardous materials from vacuum black water (BW) pipelines.

Designed to address the intricate demands of maintaining vacuum systems, which are susceptible to malfunctions caused by foreign objects such as cloth pieces, towels, and metal, and plastic parts, CAS is indispensable. These items frequently damage the rotating and sealing components of vacuum pumps, leading to costly repairs and downtime.

CAS operates as an automatic system controlled by an intelligent PLC (Programmable Logic Controller), seamlessly separating and ejecting all hazardous objects collected in its catching vessel without compromising vacuum or water flow within the system. This process occurs within a rapid 5-second cycle, ensuring an uninterrupted flow of black water.

How It Works:

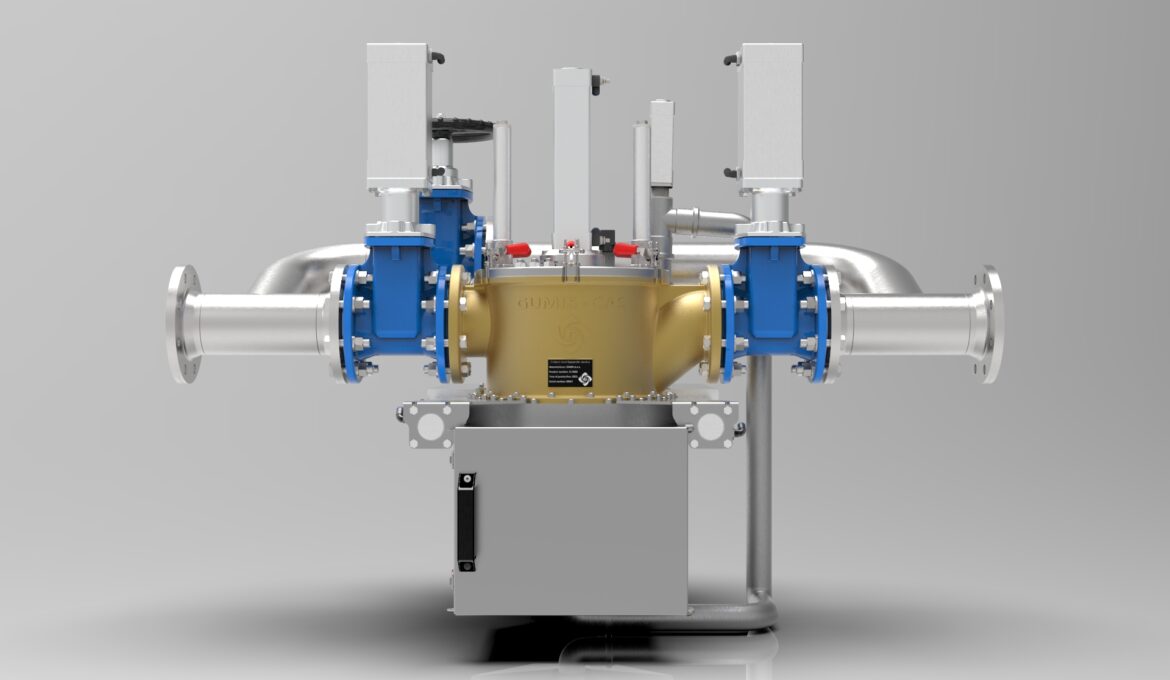

CAS operates in two distinct states: flow state and ejection cycle.

During the flow state, hazardous objects entering the BW system are strained against an array of catching systems within the CAS catching vessel. This system effectively traps items such as rags, clothes, and hard paper towels while allowing sewage sludge to pass through to the vacuum pump. Additionally, the system acts as deflector, stopping harder objects like screws and corks.

During the flow state, hazardous objects entering the BW system are strained against an array of catching systems within the CAS catching vessel. This system effectively traps items such as rags, clothes, and hard paper towels while allowing sewage sludge to pass through to the vacuum pump. Additionally, the system acts as deflector, stopping harder objects like screws and corks.

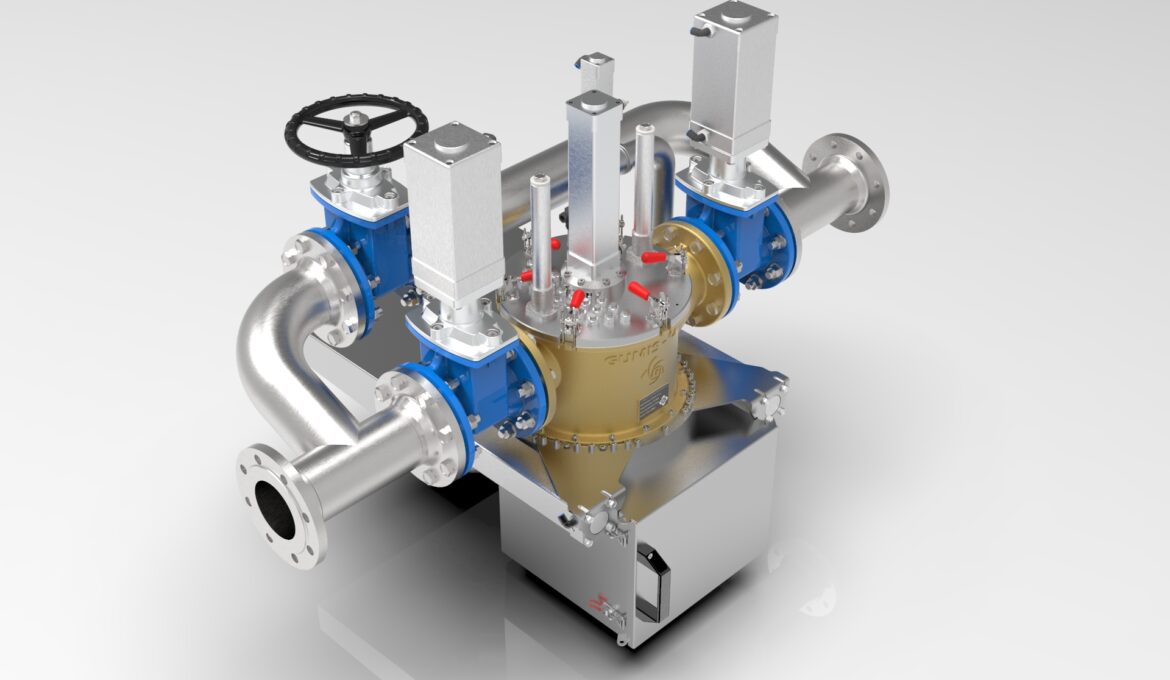

The ejection cycle occurs periodically, typically every few hours, depending on the average BW flow rate. During this phase, the contents of the catching vessel are scraped from its system and emptied into a disposable catching net located within a water-sealed waste bin. The net can be easily replaced, ensuring a swift and hygienic waste disposal process.

Advantages Over Competitors:

Automated ejection cycle streamlines operation

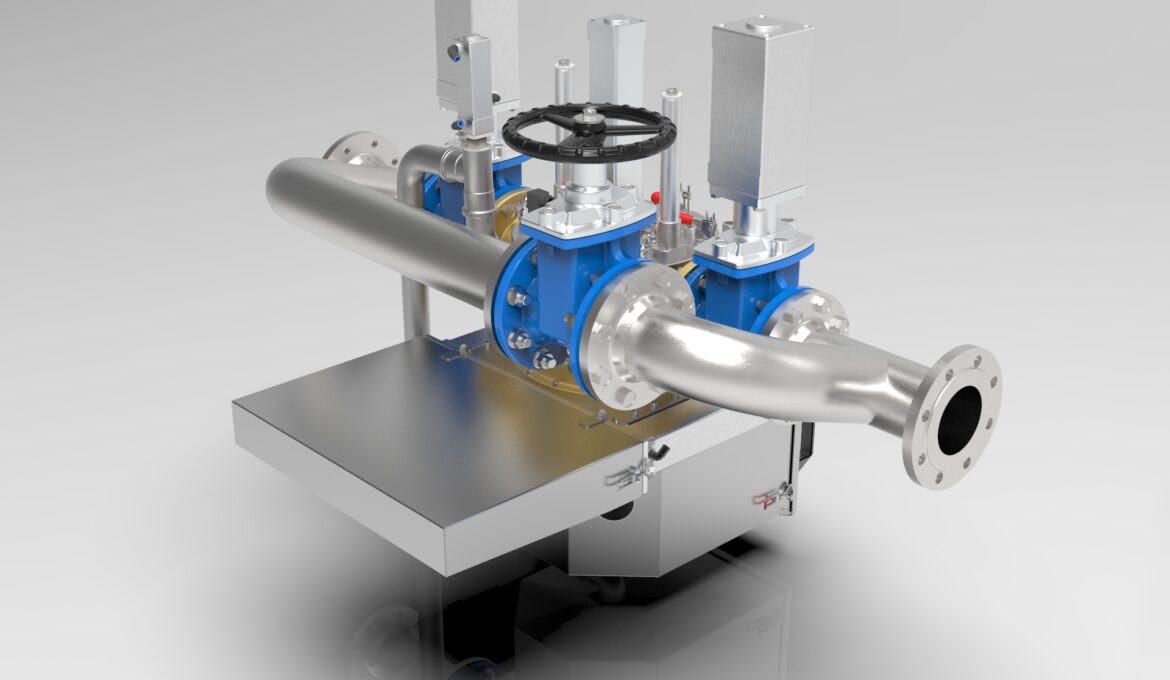

Hygienic waste disposal eliminates direct contact with waste materials

Minimal interruption to the flow of black water during the ejection cycle ensures uninterrupted toilet operation

Smaller catching vessel size allows for more frequent waste ejections

Integrated bypass facilitates maintenance procedures

No loss of vacuum or water from the system during the ejection cycle

Waste disposal is independent of the ejection cycle, offering flexibility

User-friendly design requires minimal knowledge for waste disposal

Enhanced efficiency prevents vacuum pump malfunctions and quickly offsets maintenance costs

In summary, CAS sets a new standard for automated BW system cleaning, offering unparalleled efficiency, reliability, and cost-effectiveness.