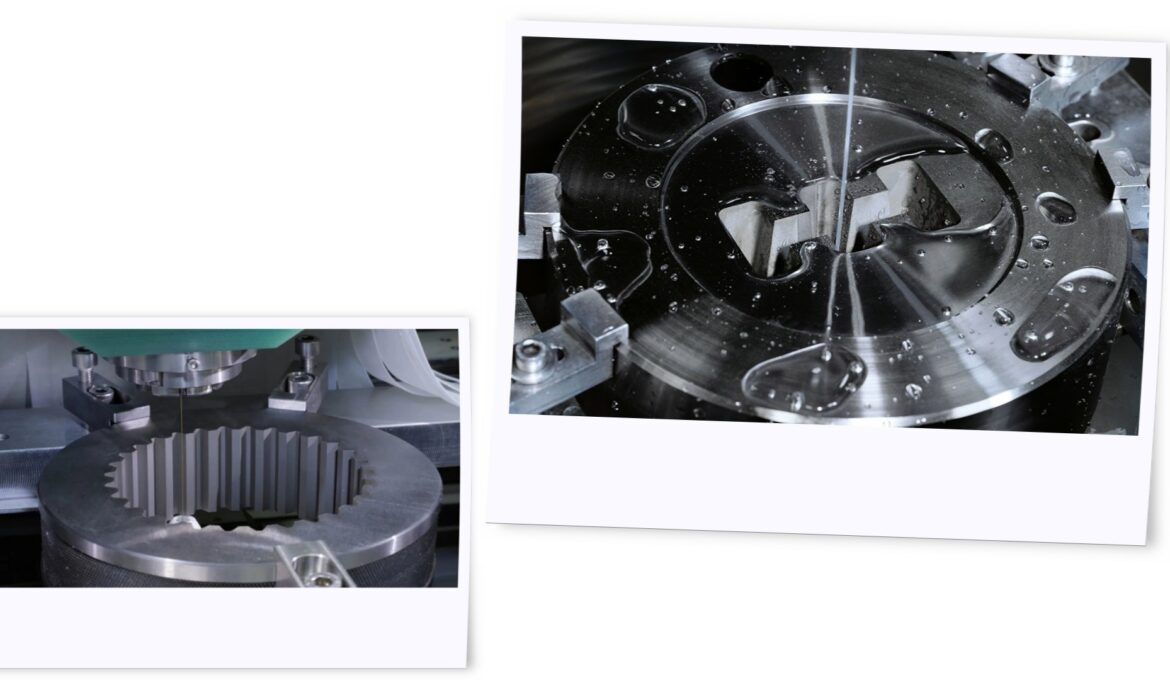

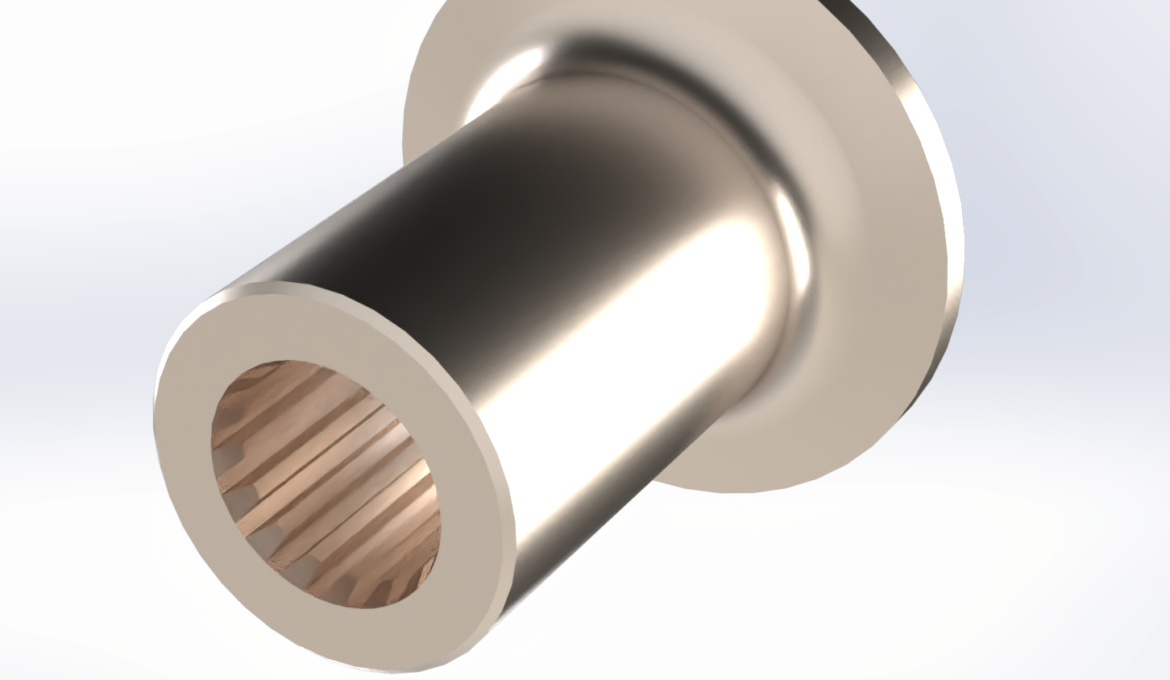

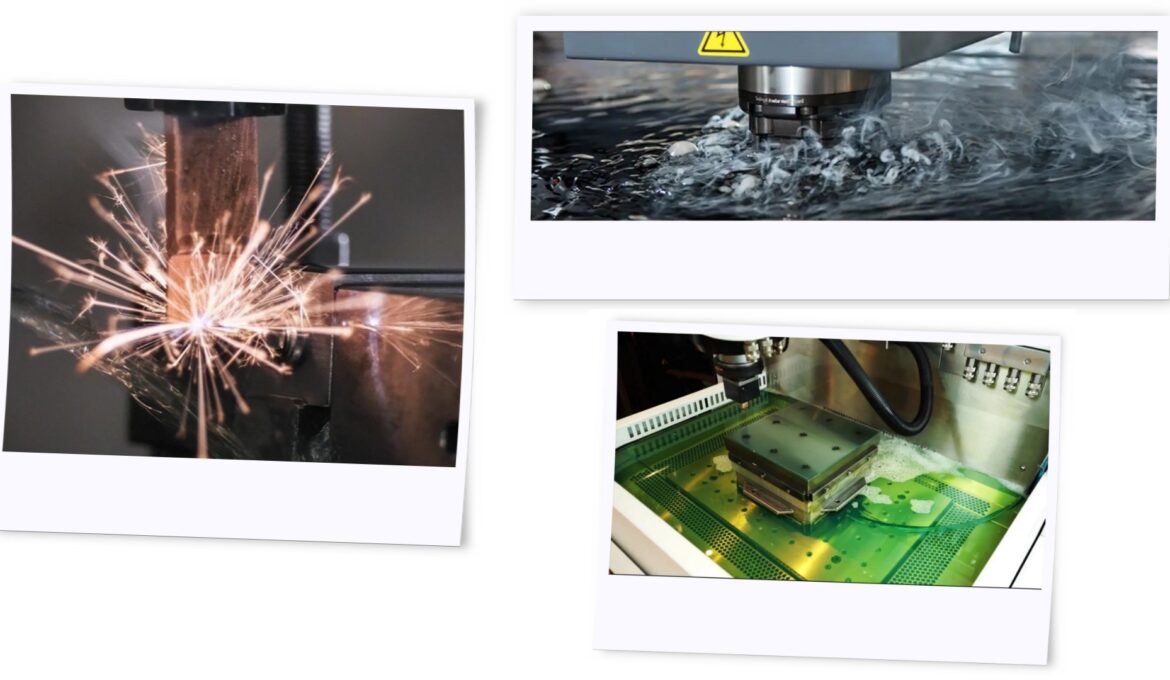

CNC Eroding

Electrical discharge machining (EDM) is a method primarily used for hard metals or those that would be very difficult to machine using traditional techniques. Also referred to as spark machining, spark eroding, burning, die sinking, wire burning or wire erosion, is a machining process whereby the desired shape is obtained using electrical discharges (sparks) to remove material from an item.