Positive Slope

For over a decade, Gumis Flexible hose solution has helped our customers reduce guest complaints, man-hours and damages to the ship equipment with regards to the BW toilet system service. We are proud to see our product accepted and used on every major cruise ship around the globe and we are doing our part by continuously upgrading and updating the product to serve our clients better.

Why install?

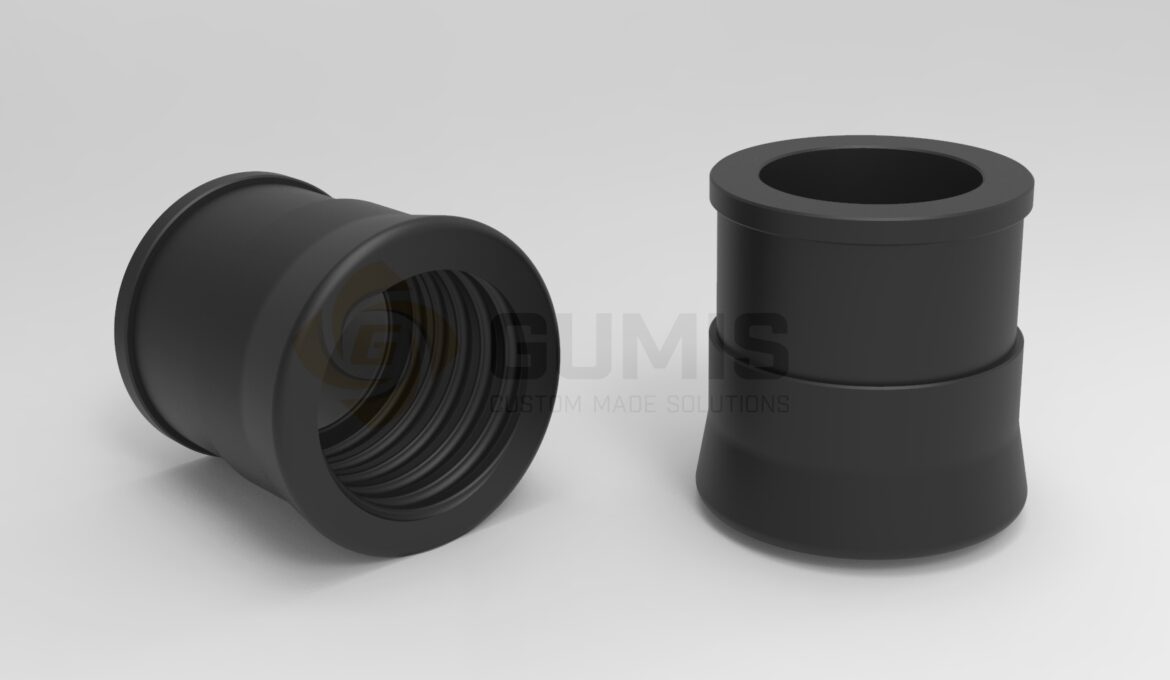

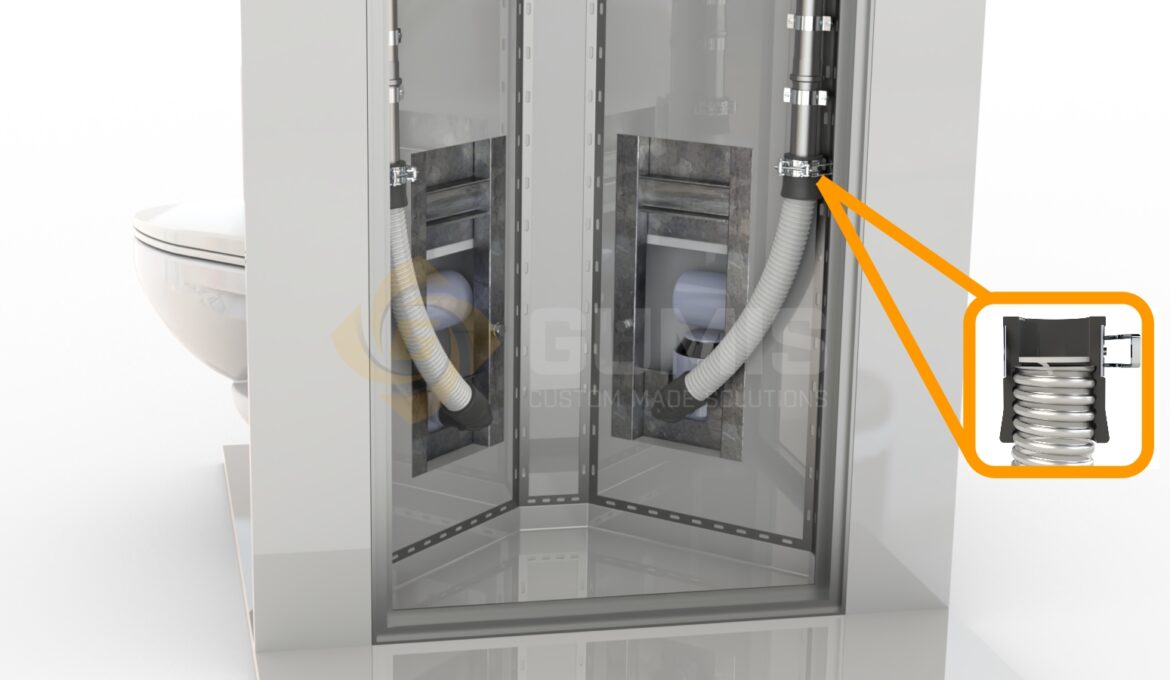

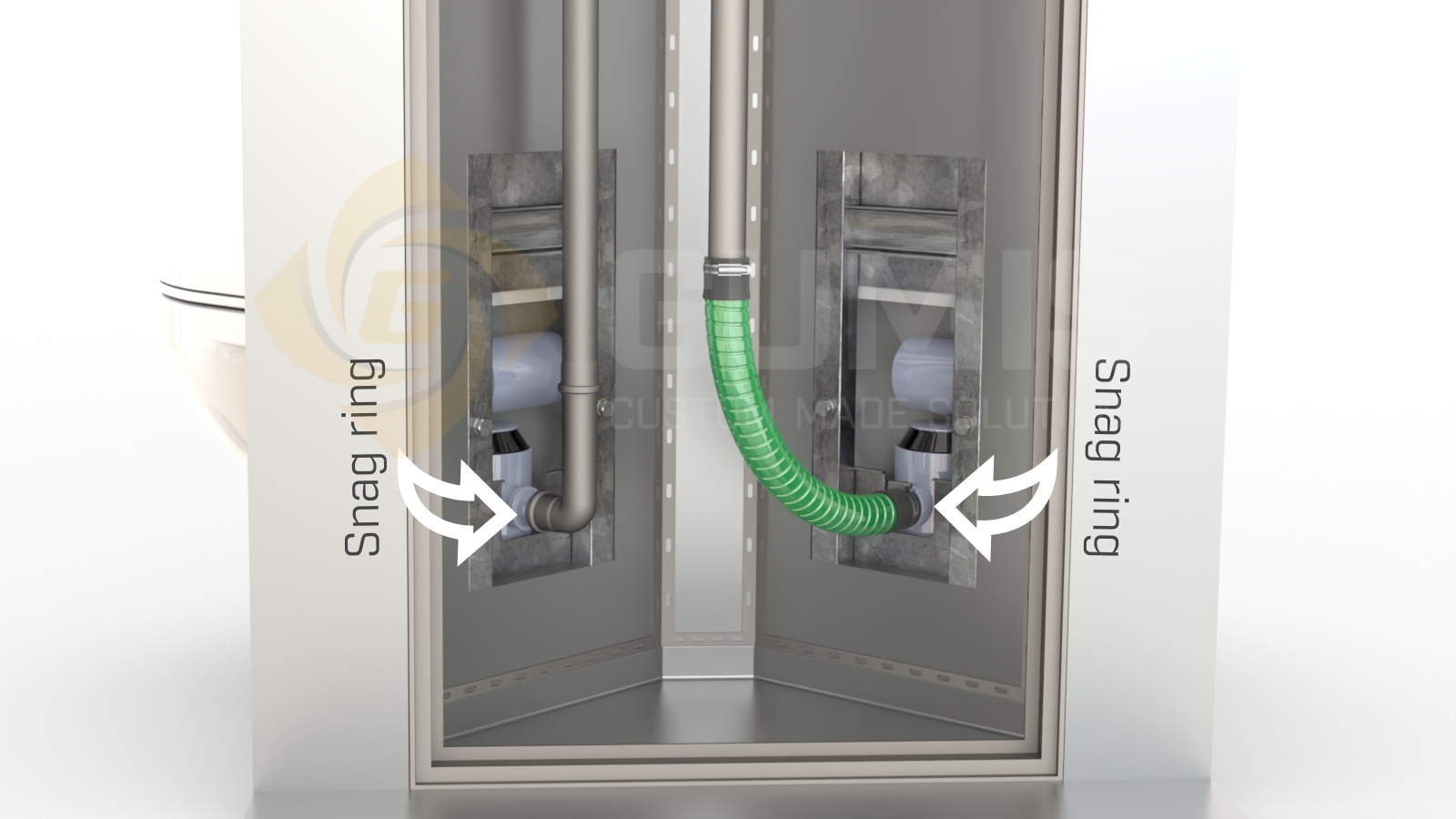

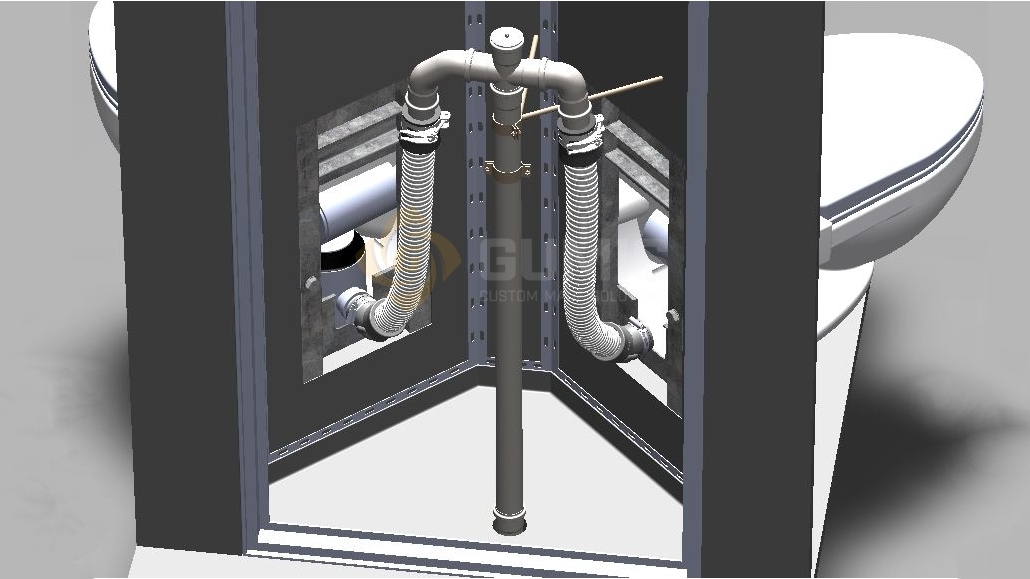

We propose to use a snag ring to catch any foreign items flushed down the toilet but in a different manner. Currently, ships either have the snag ring installed after the toilet bowl or do not have it at all.

If you do not have a snag ring, non-flushable items will clog the line (and affect a vast area of the ship with non-functioning toilets) or will end up at the pump and damage its parts, leaving you with the need to frequently service the pump.

If you do not have a snag ring, non-flushable items will clog the line (and affect a vast area of the ship with non-functioning toilets) or will end up at the pump and damage its parts, leaving you with the need to frequently service the pump.

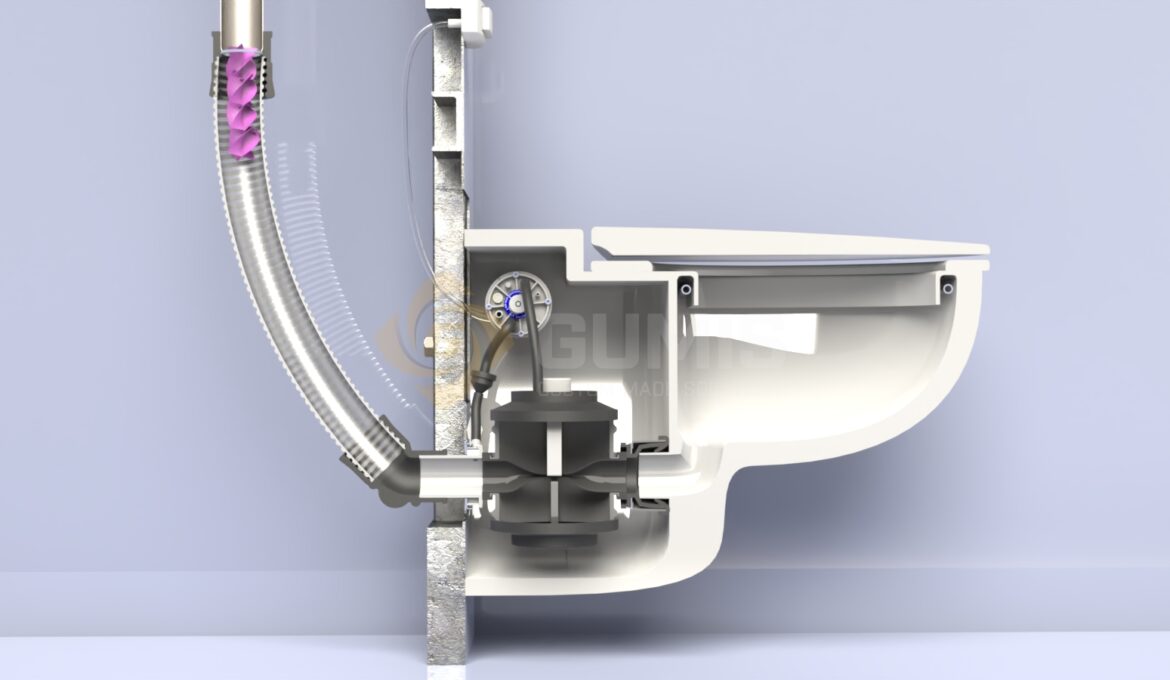

Current option with flexible hose installations with snag ring close to the discharge valve

What happens if you remove the snag ring completely:

If the snag ring is immediately after the toilet bowl, the trapped item will block the discharge valve and create a vacuum loss to the entire line (50+ toilets affected without the possibility of knowing where the clog is).

Other option with a snag ring located next to the discharge valve

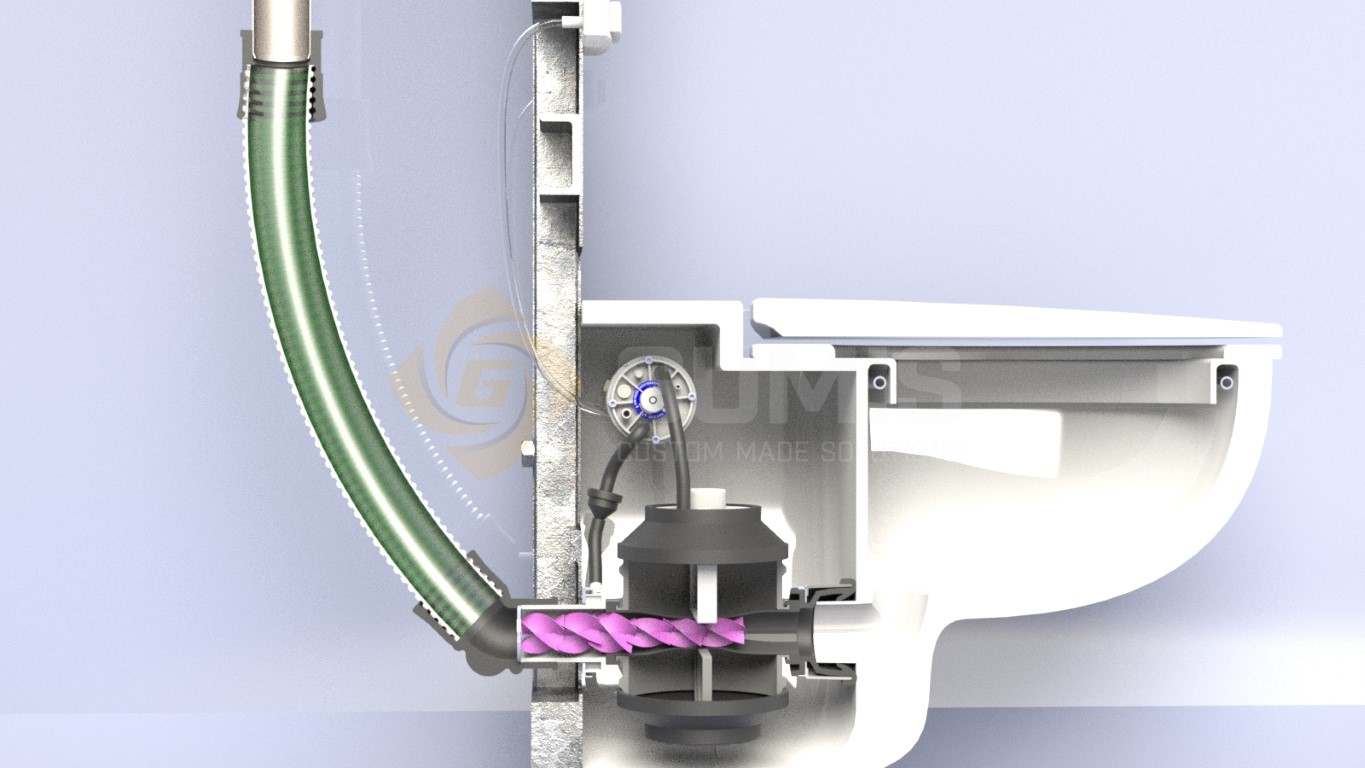

To avoid line blockages arising from the snag ring catching and blocking the discharge valve of each toilet bowl, Gumis has a patented system enabling each ship to experience the issue of the block on a single cabin only. This cuts down on maintenance time, including locating the clog, servicing the affected area and resuming the vacuum system service to the passengers.

To best utilize the solution, it should be installed with “positive slope” meaning the top part of our flexible hose is always pointing upwards (helps to avoid spilling of toilet content during the cleaning process into the locker leaving bad smell and impurities).

This way, when clogs occur and the hose is dismantled, contents of the toilet will remain in the flexible hose, avoiding extensive cleaning, bad smell and passenger inconvenience created by spillage. This also eliminates the need to frequently paint the deck under each toilet bowl service locker which gets corroded very quickly.

This way, when clogs occur and the hose is dismantled, contents of the toilet will remain in the flexible hose, avoiding extensive cleaning, bad smell and passenger inconvenience created by spillage. This also eliminates the need to frequently paint the deck under each toilet bowl service locker which gets corroded very quickly.

Gumis solution for positive slope

Toilet Not Flushing

*Example from a cruise vessel on TNF reduction. Installed in September and only 3 months after reduced from 650 to 50 pcs. of TNF´s.