Gumis Couplings

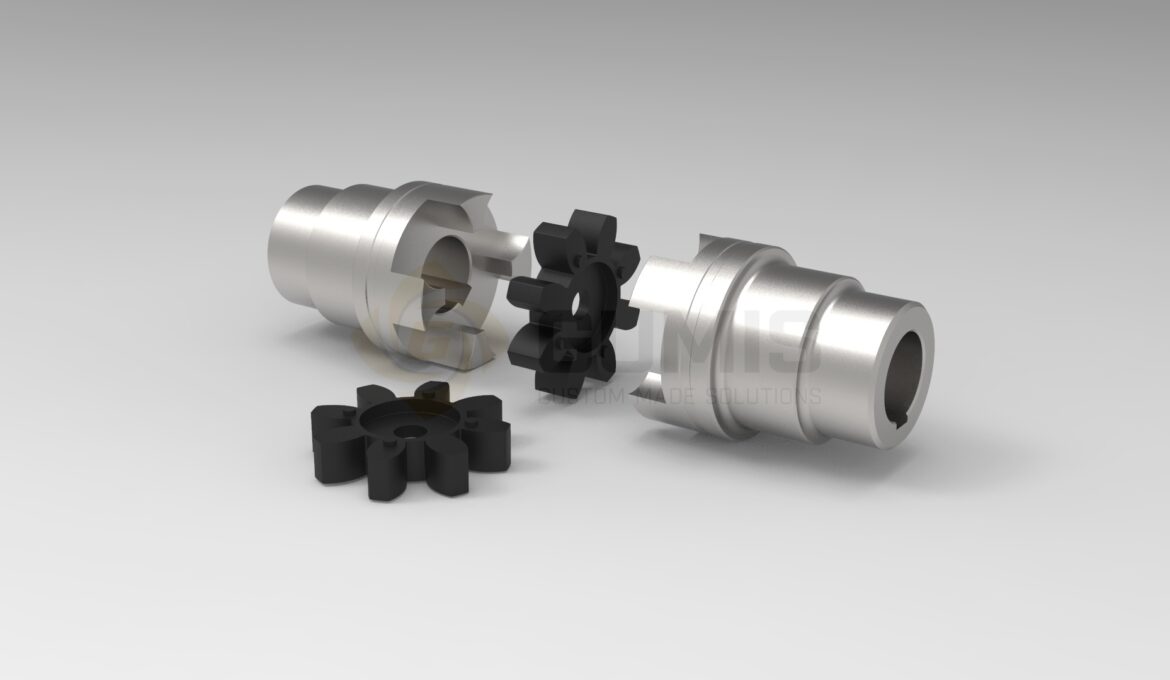

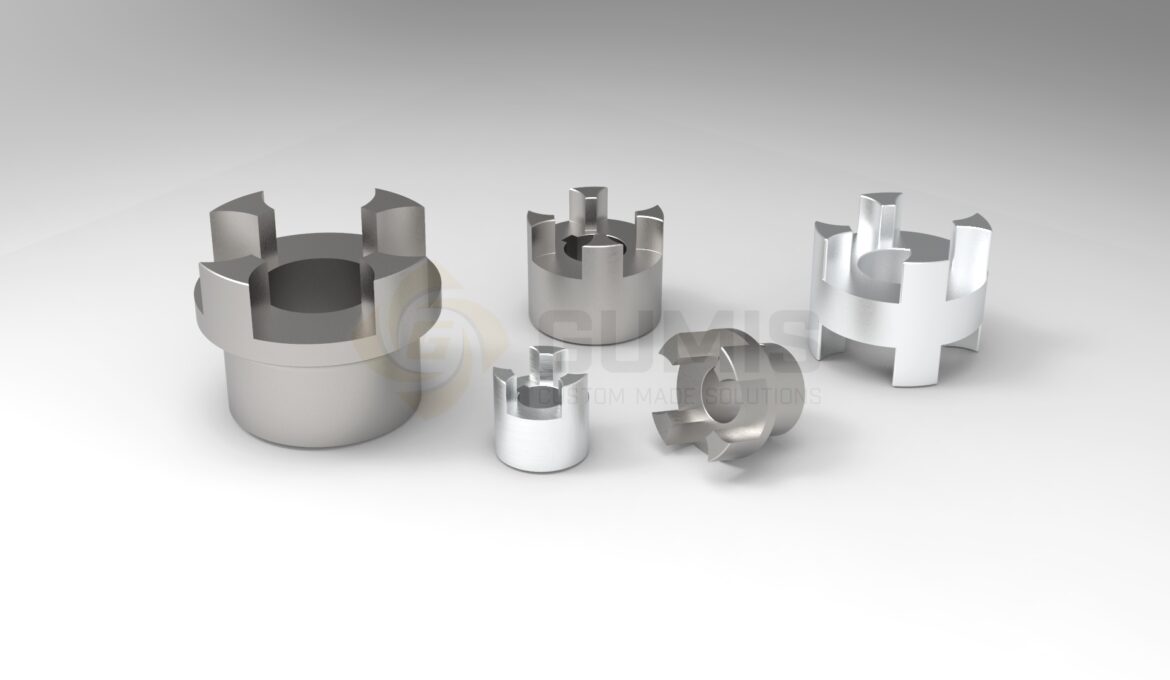

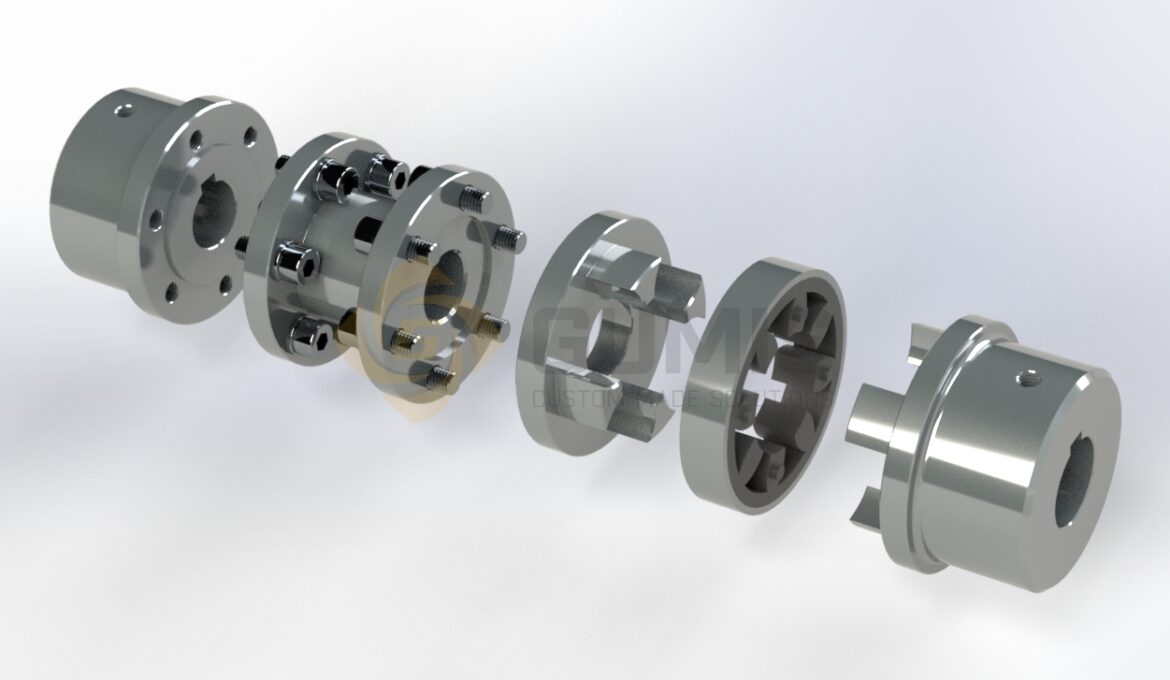

Our first coupling that was shipped as a sample to our client in 2006. is still working without any issues. More to this is it is still working with same Rubber NBR Spider. Our couplings are made of solid piece of steel/aluminum and can be made in any variety our client wish or situation requires.

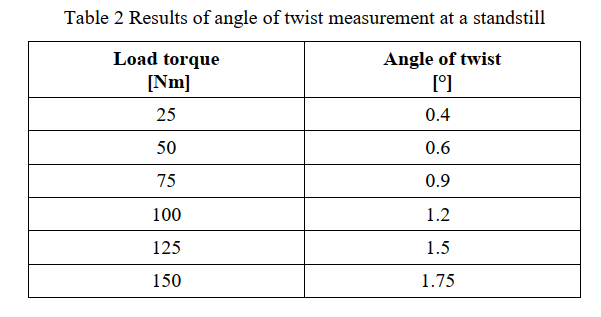

Gumis Coupling Test

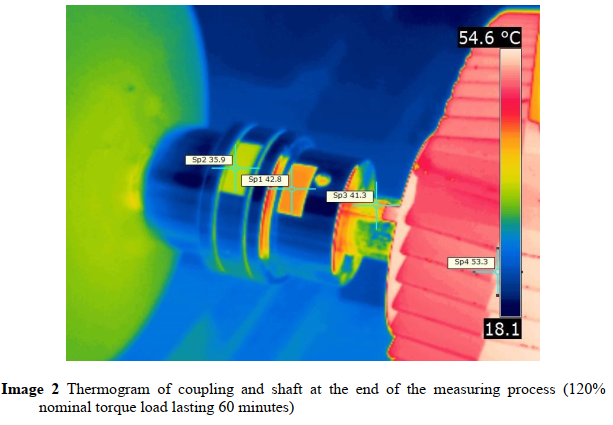

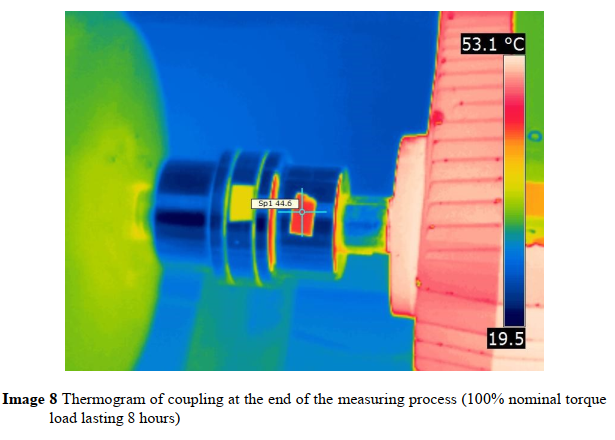

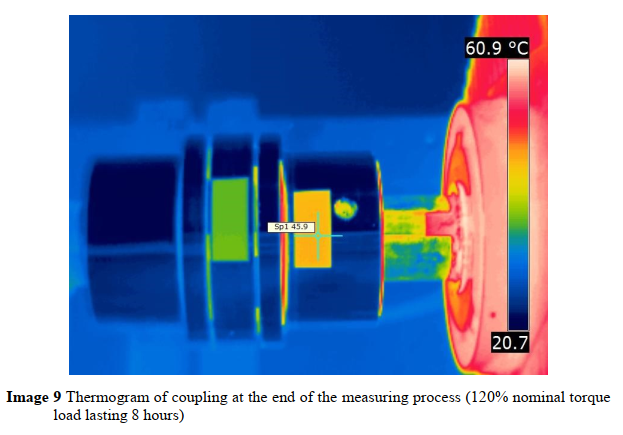

This test was conducted in the Faculty of Electrical Engineering, Mechanical Engineering and Naval Architecture in Split, Croatia. The coupling test has been conducted in the following manner:

The coupling temperature was measured using a thermal imaging camera and during the tests, there was no temperature rise which would indicate a potential problem with the drive the coupling was designed for. Moreover, the conducted tests showed no signs of mechanical damage of the elastic rubber element or aluminum coupling despite the fact that during certain parts of the tests the load torque value was (up to 50%) higher than the nominal torque of the coupling.