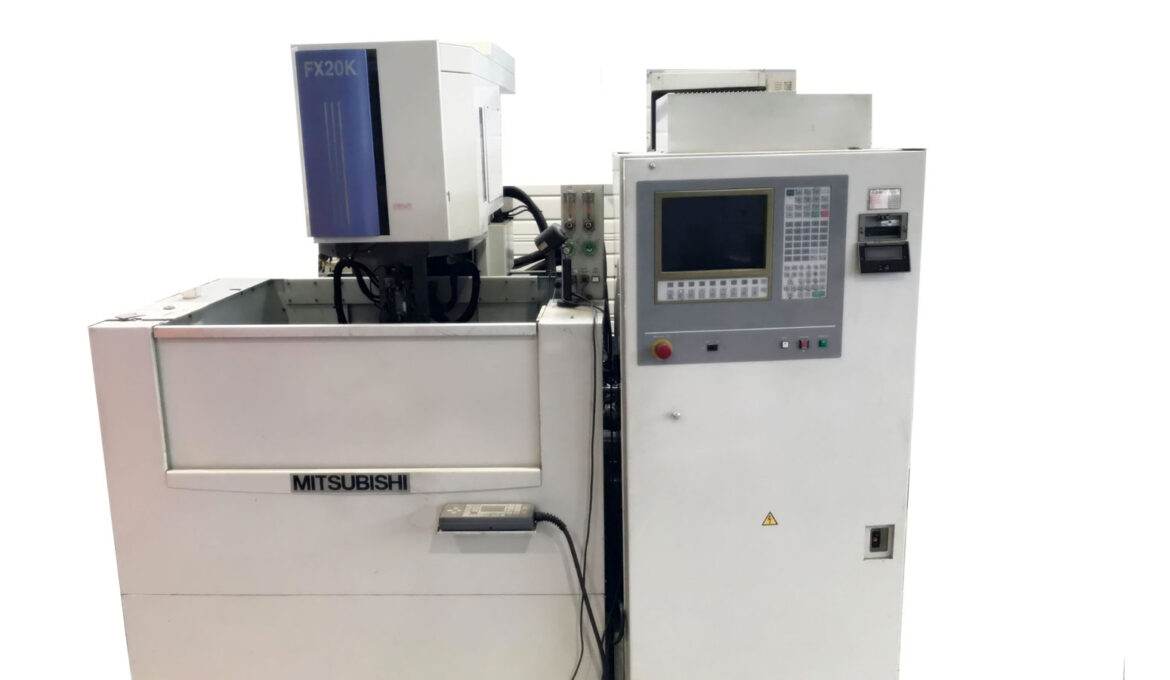

EDM MITSUBISHI FX20-K

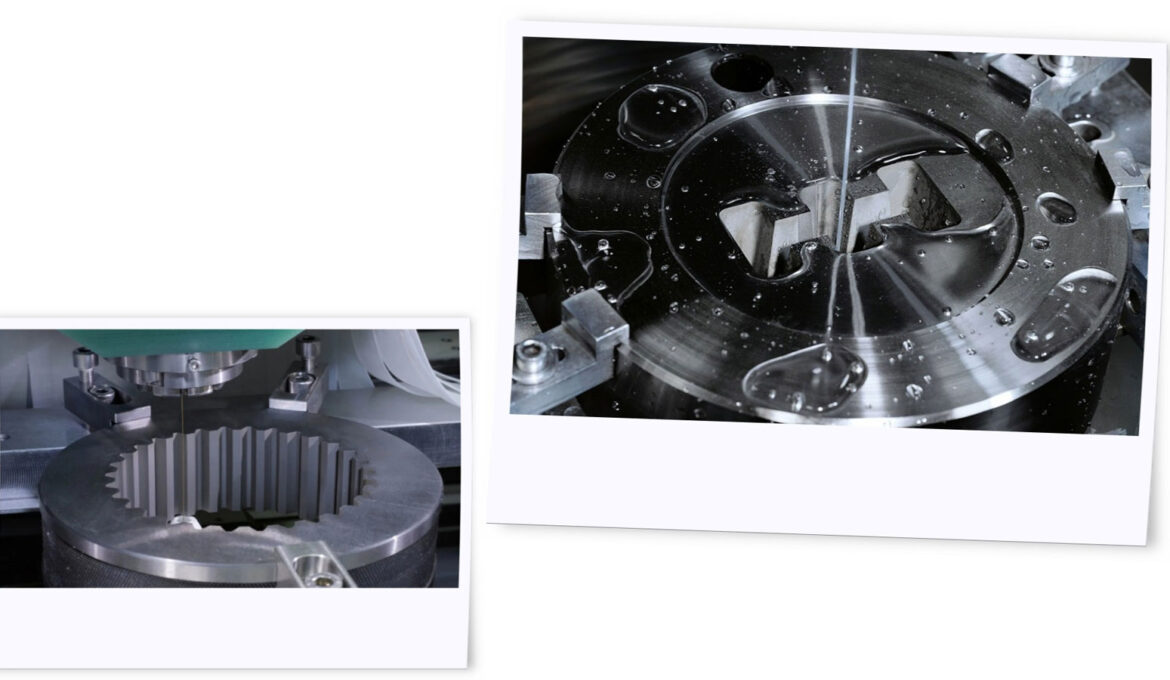

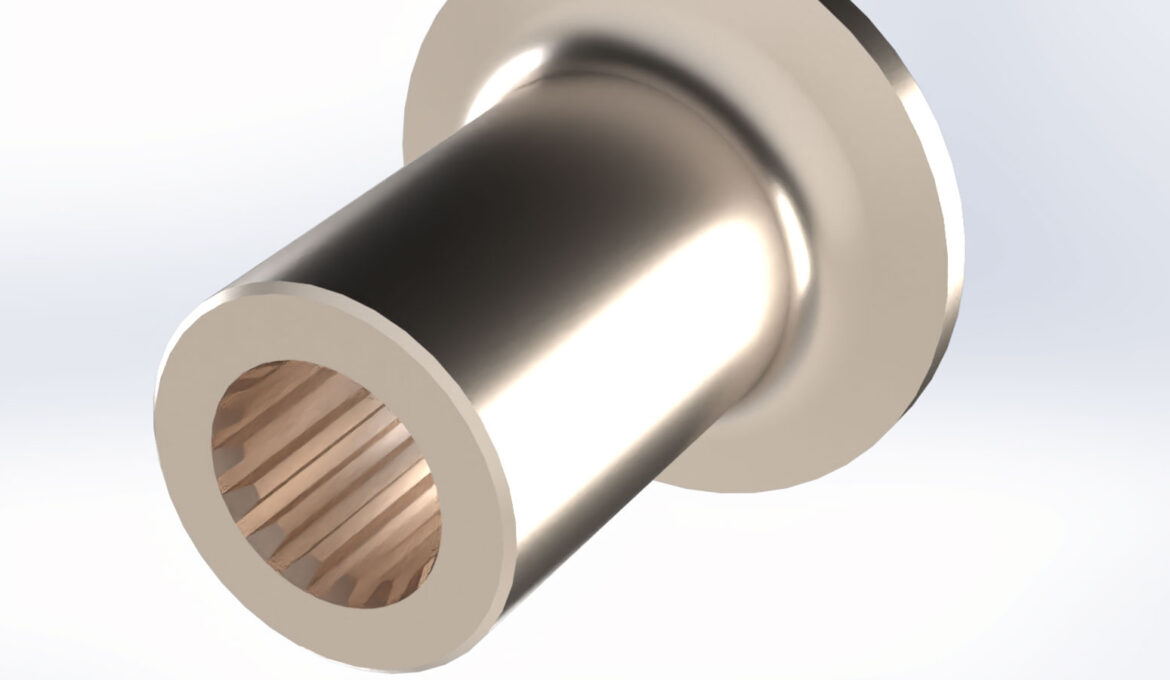

We use spark erosion methods to cut contours in hardened components or hard materials which cannot be produced by machining. Wire EDM is used to cut contours, and sink EDM is used to introduce shapes and contours on the outsides and insides. Whether drill holes with small diameters and large depths, undercuts or curved holes, there are generous limits for the component design.